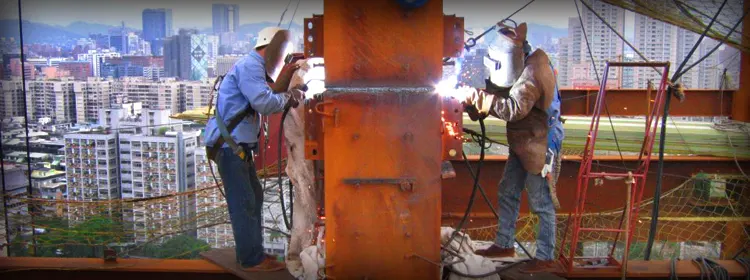

Rope Access Welding Services (Kyiv)

According to the occupational safety and health regulations, welding is classified as hazardous work, and if such welding works are to be performed at height, welders should be top-class professionals with profound safety skills. Such rope access welders should meet a number of stringent requirements: to have at least a level 5 certificate in industrial rope access, an annual certificate evidencing welder qualification test, to undergo an annual medical examination as well as to have good skills needed for welding in unsupported or confined space.

Alp Star has highly skilled and certified rope access welders. Their reliable experience and expertise as well as good faith approach to the assigned tasks make our Company be able to perform the most complicated welding works at height: reinforcement of steel structures, installation of advertising structures, replacement of damaged sections of pipelines, installation and dismantling of floor trusses, etc.

The estimation approach used to calculate the cost of welding works performed at height differs a little bit from standard ones. If an average steel structure manufacturing company equates the cost of works to the cost of materials, the cost of rope access welding works is estimated by taking the following considerations into account:

- the height at which welding works to be done;

- any preparatory arrangements (marking the surface by using theodolite, production of additional suspended platforms and anchors for assistant workers);

- type of metal profile (grade);

- complexity of structure;

- conditions in which materials to be lifted;

- dimensions of individual structural connections;

- requirements to joints;

- any anti-rust protection jobs.

In some cases, it is impossible to take into account all considerations due to some reasons, therefore, welding works will be invoiced on hourly or shift basis.

By hiring our experienced rope access welders, you will get the best quality to price ratio and reasonable duration of works. Please call us at +380 67 258 2999 or e-mail us at alpstar.kiev@gmail.com

Safe performance of welding works at height requires to take a wide range of safety measures and to carry out a host of preparatory works. Such measures can include not only regulatory and theoretical research, but also field (on-site) operations.

Rope access welding services are associated with particularly high risk, that’s why it is important to give special attention to occupational and fire safety briefings, sanitation and hygiene standards (for indoor welding). Unlike standard works at height, a welder should use steel chains as safety harness. Clothes of industrial rope access welders should be not only comfortable, but also thick to protect from burns. A working area below a welder is wrapped with a warning or barricade tape. The welding equipment and tools for work at height should be extremely lightweight, compact, reliable and efficient.

In many cases, to erect complex unit-forming and heavy elements of steel structures, it is necessary to use lifting pulley systems or to manufacture temporary suspended platforms for workers engaged in erection process but not in welding.

When there is a challenge to sharply limit the duration of welding works at height, Alp Star employees can train even average welders having no acrophobia (fear of heights) how to safely use rope access techniques.