Steel Structure Painting (Corrosion Protection)

It is hard to imagine a modern world without metals. Almost 50% of load-bearing structures in construction of high-rise buildings, plants, bridges, oil storage facilities and gas pipelines is made of steel. Sad to say, but in addition to a number of positive features, steel has a number of drawbacks. The main one is corrosion, i.e. rust. Under its influence, the service life of steel structures dramatically decreases.

Alp Star offers comprehensive solutions to problems caused by corrosion of steel structures:

- Steel structure cleaning (hand-tool cleaning, sandblasting, water jetting);

- Surface preparation for corrosion protection;

- Application of primers;

- Painting of steel structures for various purposes (manual and by using automated coating equipment).

Unfortunately, so far, there is no universal corrosion protection method. That’s why it is better to look to corrosion source, corrosion pattern, and rust grade. Depending on purpose of steel structure and environmental exposure effects, our experienced rope access specialists will select suitable protective coatings, define a proper number of coating layers, required intervals between application of layers, thickness of each individual layer and the whole coating.

Feel free to contact our specialists to get free-of-charge consultation or to hire our professional services at +380 67 258 2999 or by e-mail: alpstar.kiev@gmail.com

Everything created has its own life time and is exposed to day-to-day wear and tear, and metal is no exception. While in use, steel structures are inevitably affected by rust and anti-corrosion coating failure. Therefore, an issue of structure protection and repainting will come up sooner and later.

Corrosion Protection (Kyiv). Rust protection and prevention mean a process of applying one or more layers of special organic or inorganic protective coatings to the surface of steel structures with the intent of inhibiting or preventing corrosion.

Painting and corrosion protection coating works are regulated by ISO 8501-1: Preparation of steel substrates before application of paints and related products. Visual assessment of surface cleanliness, GOST 12.03.005-75: Painting works. General safety requirements, and GOST 12.3.016-87: General safety requirements for corrosion protection.

The corrosion protection process is divided into the following steps:

- surface preparation (cleaning, degreasing);

- application of primer;

- application of paint.

On average, successful corrosion protection depends by 75% on proper, thorough preparation of surface and only by 25% on the quality of paint coats and their application methods. The main goal of surface preparation is to remove mill scale, rust and other contaminants.

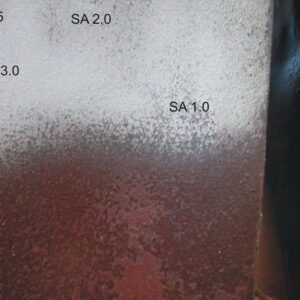

There are 7 levels of surface preparation according to the ISO standard:

- ISO-St: Hand and power tool cleaning

- ISO-St2: Thorough hand and power tool cleaning

- ISO-St3: Very thorough hand and power tool cleaning

- ISO-Sa: Blast cleaning

- ISO-Sa1: Light blast cleaning

- ISO-Sa2 and ISO-Sa2,5: Thorough blast cleaning

- ISO-Sa3: Blast cleaning to visually clean steel

As a result of surface preparation by using hand-tool or blast cleaning, it is important to get an appropriate surface roughness levels, which will ensure a desired level of adhesion of paint coats to the steel structure. Surface roughness profile parameters are referred as Rz, Rt, Ra.

Depending on the surface preparation requirements, in addition to the above listed types of cleaning (power- or hand-tool cleaning, sandblasting), the following ones are also used:

- Water jetting cleaning: it is a process of cleaning a steel structure surface by a high-pressure water jet without dust generation.

- Wet blast cleaning: it is a process of cleaning a surface with water and abrasive agent.

- Thermo-abrasive blasting: it is similar to abrasive blasting, but differs by a high-velocity gas stream flow and its temperature. It is a technology of impact on a working surface by a high-temperature supersonic flow stream consisting of abrasive particles. The thermo-abrasive blasting ensures simultaneous de-dusting, degreasing and metal surface activation, that is why no additional surface treatment is required.

- Dry-ice blasting: it is a process of cleaning by using carbon dioxide. This method involves treating a surface with dry ice pellets accelerated in a pressurized air stream. By hitting a structure, pellets intensely cool it down, which, in its turn, makes a top layer of dirt crisp and fragile, reduces adhesion to the surface (of a steel structure). As a result, layers of dirt peel off from steel and are removed by high-pressure pellet stream.

Most commonly, modern paint coats are multi-layer systems, the main purpose of which is to create a long-lasting durable protection of steel structures against corrosion appearing due to exposure to various environmental factors. The tendency to use multi-layer protective coating is caused by a desire to obtain efficient corrosion protection of a steel structure and different functional features of each separate layer of paint.

Depending on the operational environment of a steel structure, corrosion protective systems can be of various types. But, notwithstanding this, in most cases, there are three main types of layer, namely primers, intermediate and finishing layers.

A primer is a first coat applied on a pre-treated steel surface. It has a quite good adhesion to structural steel and simultaneously ensures a desired level of gripping with the next paint coat.

Primers are selected depending on the operational environment of a steel structure and a type of paint. Primers can be of such types:

- Passivating

- Insulating

- Phosphating

- Protective

- Rust converters.

Passivating primer reduces the reactivity of a metal and makes the surface passive in terms of electrochemical oxidation, which stops corrosion.

Insulating primer prevents penetration of oxygen and moisture. It is frequently applied on ferrous metals.

Phosphating primer helps to make painting of a zinc coated surface, to which almost all paint coats have no enough adhesion, more easy.

Protective primer contains up to 80% of metal pigments (lead, zinc powder and magnesium-zinc alloy). A high-density impermeable film is formed due to corrosion, and it interacts with electrolyte of paint coat containing zinc powder.

Rust protector is applied when to clear a surface to be painted is rather difficult. It helps to remove a top loose coating.

The final step of corrosion protection is painting of a steel structure. In order to properly select a type of paint coats, it is necessary to consider a number of factors as follows:

- type of structural material;

- environmental conditions;

- specified life span of structure;

- handling ability of paint application;

- requirements to exterior appearance;

- ecological, sanitation and hygiene, and fire safety standards;

- cost-benefit assessment.

Method of paint coating application should correspond to their physico-chemical properties indicated in manufacturer’s specifications. There are roughly four application techniques, namely: brush, roller, pneumatic spraying and airless spraying.

Brush application is a low-efficient and slow application technique. However, this method is the most suitable for painting complicated structures as the use of spraying equipment is associated with a considerable loss of paint. Almost all thick-layer coatings (over 120 µm) should be applied by using airless spraying technique because brush application would fail to ensure a desired result. To get a desired thickness of coating by using brush, it can be necessary to repeat application of paint by brush several times.

Roller coating is suitable to paint large flat surfaces and it is more efficient than brush application. Roller is often used to apply decorative paints. But, just like with brush application, to get a uniform coating of desired thickness by using a roller is also rather difficult. It is necessary to carefully choose a type of a paint roller, length and thickness of nap.

Pneumatic (air) spraying is a fast and commonly used method of paint application. Coating material is mixed with low-pressure air and sprayed onto the surface. The equipment for such techniques is budget-friendly and easy to operate, but to achieve a uniform spraying and a flawless film of paint coating is rather challenging as it is important to use a proper ratio of air pressure, volume and flow stream of liquid. Such spray painting is associated with a loss of excessive quantities of paint due to its atomization in the air. Moreover, this application technique is impossible to use to apply high-solid paints for thick-layer coatings.

Airless spraying is a method where paint is not mixed with air but propelled at very high pressure through nozzles. The main advantages of this application technique are the following: 1) it is possible to coat steel structures with thick-layer high-solid paints without reducing or thinning the paint; 2) higher output; 3) low loss of coating material.

Paint Application RequirementsWhen applying anti-corrosion coatings, it is required to consider the following important factors:

- paint temperature;

- weather conditions;

- surface temperature.

Paint and coating application cannot be performed:

- in case of very humid environment or mist or when precipitations are forecasted;

- in case the ambient temperature is below the temperature required for paints to dry or the temperature limit indicated in specifications;

- if there is condensation of the metal substrate or condensation can occur during initial drying;

- on wet or ice-coated structures.